- 2024

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- 2010

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- 2000

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- 1990

-

-

-

-

-

-

- 1980

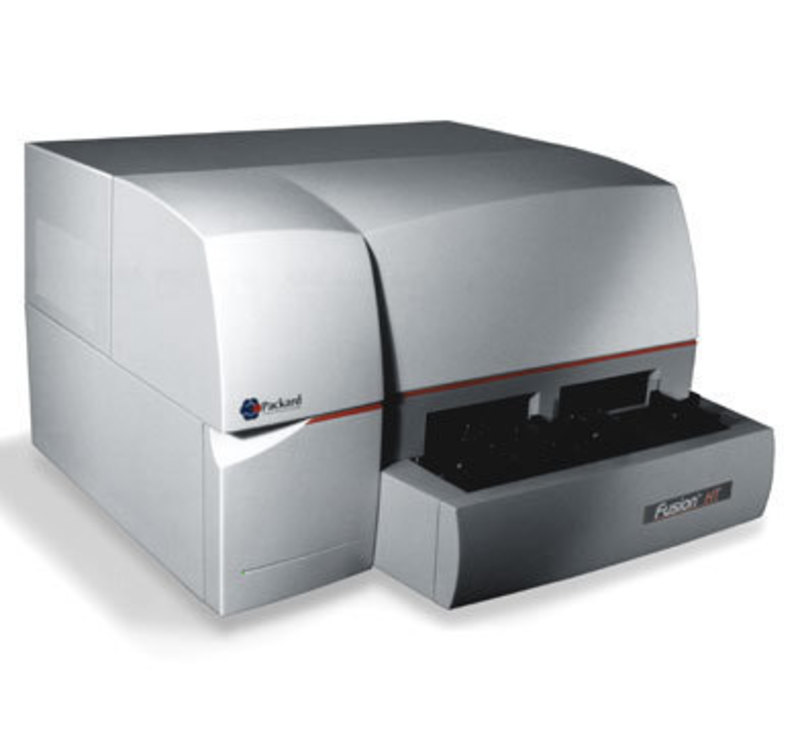

Packard (PerkinElmer)

Kryptor Blood Analyzer

Design Team: Cesaroni Design & Packard

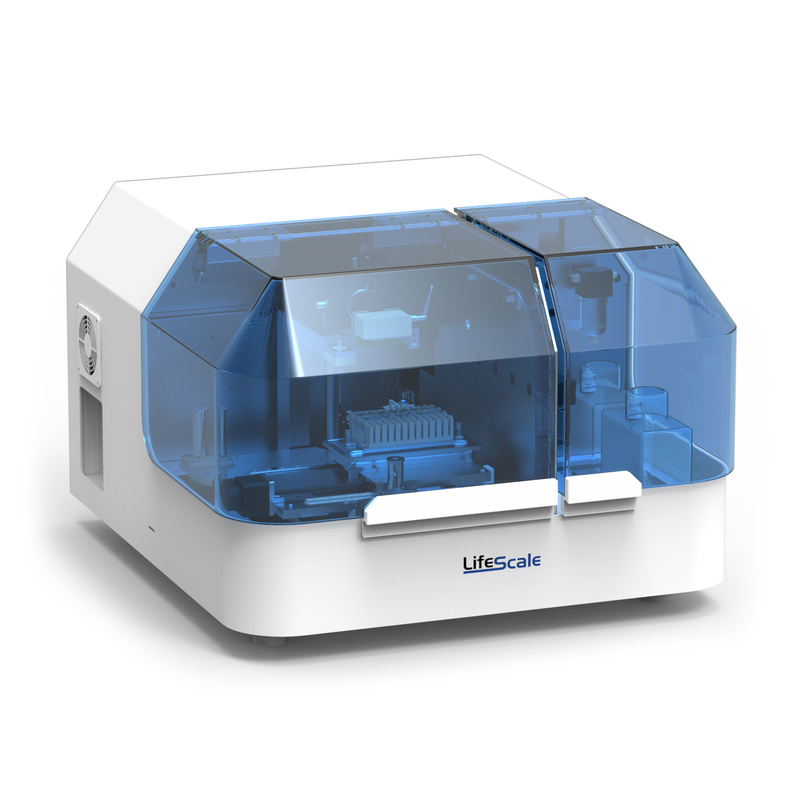

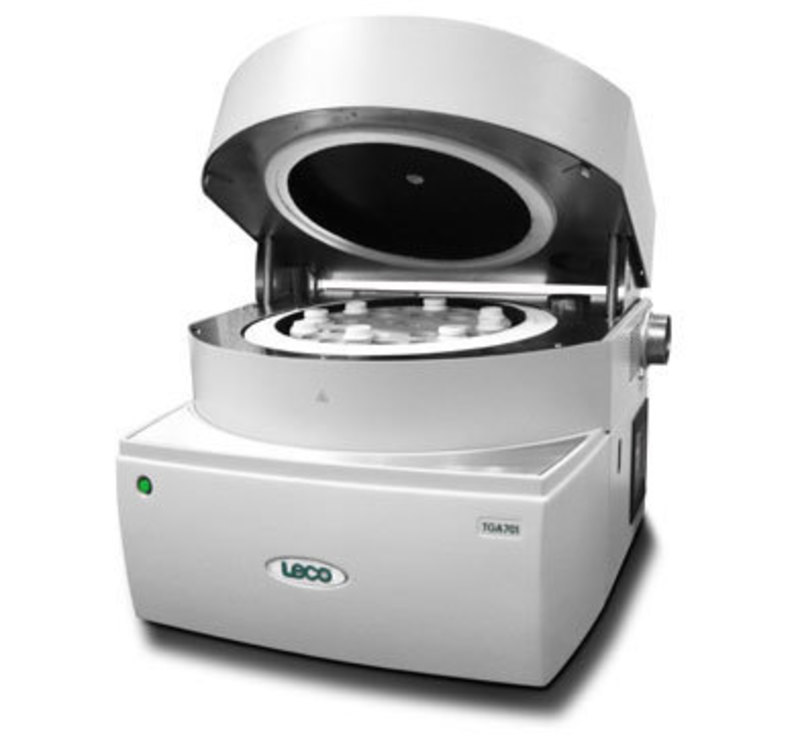

Cesaroni Design collaborated with Packard Instruments to develop a new medical product for the modern clinical laboratory. The project challenge was to incorporate our client's new technology in an instrument that tests blood samples for antigens.

User interface was a primary objective in the medical product design process. The design team built a foam model to evaluate ease of use and analyze service of the machine.

As a result the product designers created one unit with two separate modules. This design approach minimized the machine's movement for the user to gain access to internal components.

The form language deviates from the traditional box-look of past analytical equipment. Soft contours and crowned surfaces deem inviting to the user and are complementary to laboratory surroundings.

The frame is welded aluminum with necessary mounting accessories for analytical modules. Exterior enclosures are rigid cast polyurethane made from silicone rubber molds.

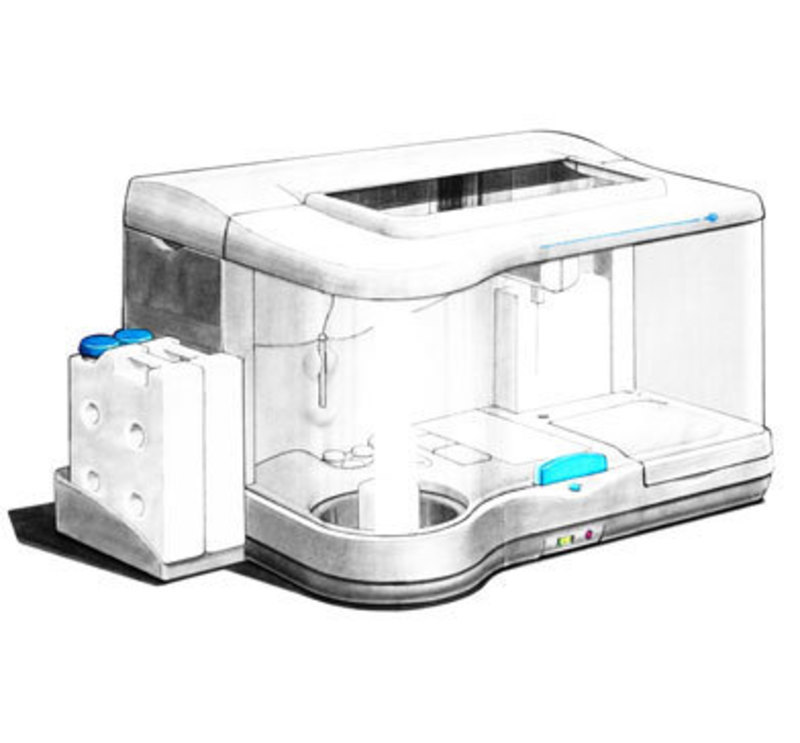

Packard (PerkinElmer)

Kryptor Blood Analyzer

Design Team: Cesaroni Design & Packard

Cesaroni Design collaborated with Packard Instruments to develop a new medical product for the modern clinical laboratory. The project challenge was to incorporate our client's new technology in an instrument that tests blood samples for antigens.

User interface was a primary objective in the medical product design process. The design team built a foam model to evaluate ease of use and analyze service of the machine.

As a result the product designers created one unit with two separate modules. This design approach minimized the machine's movement for the user to gain access to internal components.

The form language deviates from the traditional box-look of past analytical equipment. Soft contours and crowned surfaces deem inviting to the user and are complementary to laboratory surroundings.

The frame is welded aluminum with necessary mounting accessories for analytical modules. Exterior enclosures are rigid cast polyurethane made from silicone rubber molds.