- 2025

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- 2010

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- 2000

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- 1990

-

-

-

-

-

-

- 1980

Gendex Dental Systems (KaVo)

Orthoralix® 8500 Panoramic X-Ray Unit

Design Team: Cesaroni Design & Gendex

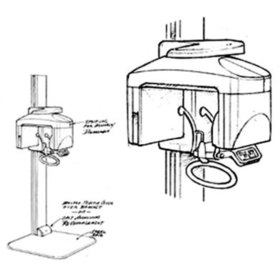

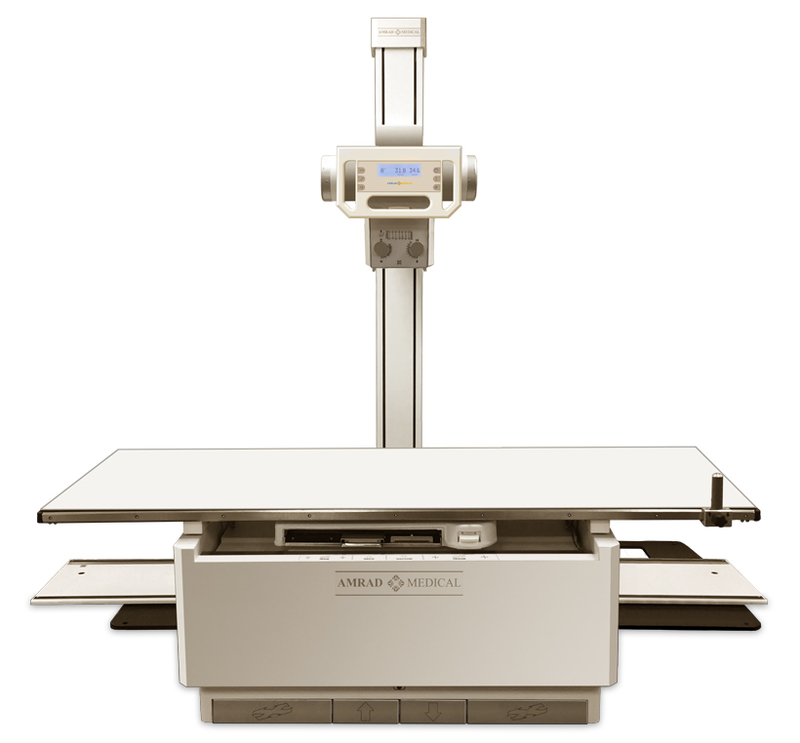

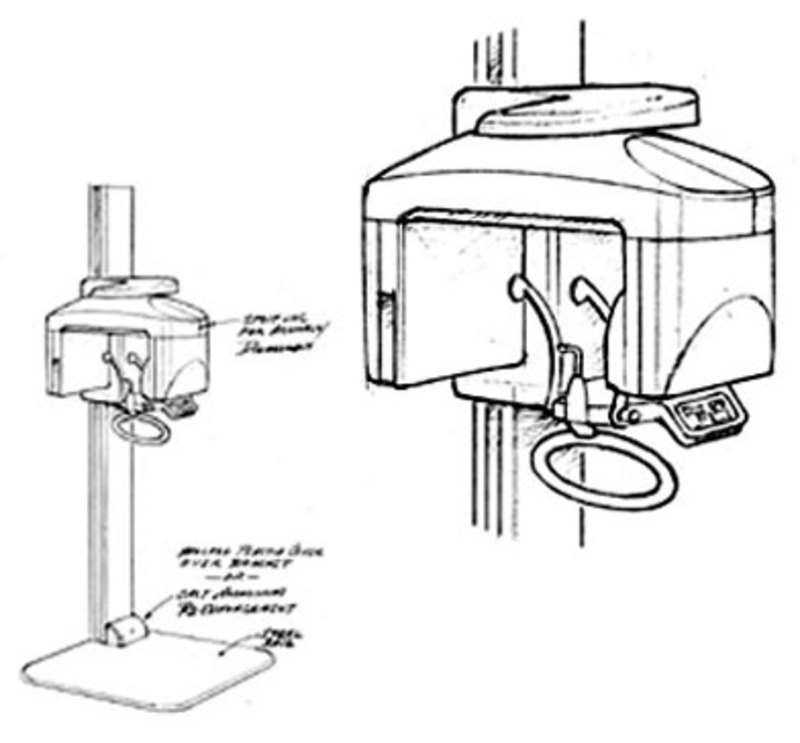

Gendex Dental Systems and Cesaroni Design product designers developed this diagnostic imaging product. The engineering was handled by our client, while we focused on optimizing a lightweight structure. We worked closely with our client's engineering team to understand assembly and service requirements.

Multiple medical product design concepts were generated, all of which satisfied the project objectives. We then implemented the chosen concept in 3D CAD. The resulting part files were shared with Gendex's development team for further review.

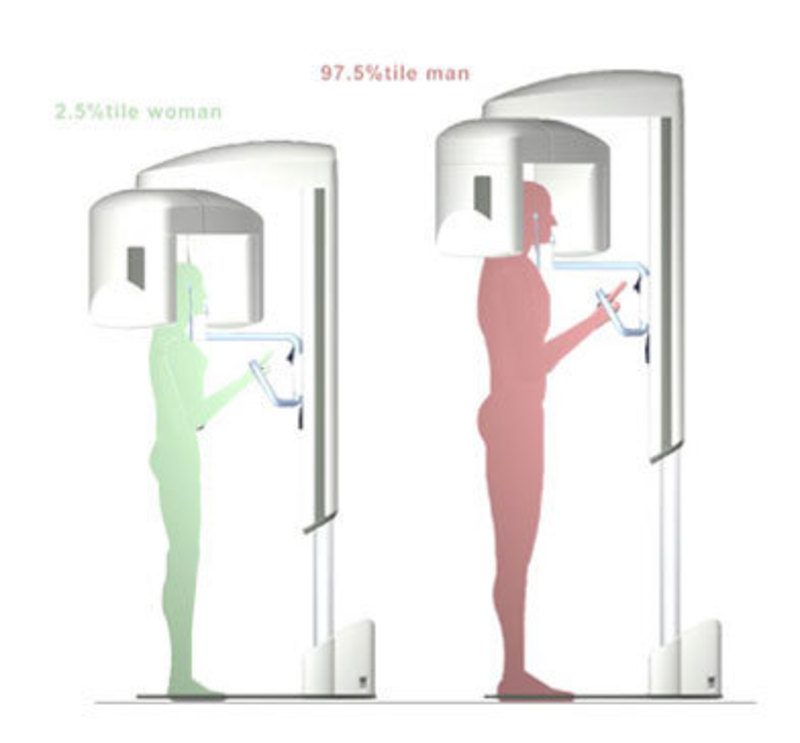

The adjustable telescopic column is one of the most significant elements of the design. This component makes the unit extremely compact. It also enables the system to accommodate patients of all sizes, including children and wheelchair-bound patients.

Ergonomic diagrams assisted the development team in analyzing the design for the handlebar and chin rest so that the patient is held in a stable and comfortable position. Molded polycarbonate and carbon fiber patient supports are mounted on powder-coated handlebars.

The new product design increases workflow, giving the operator the ability to access mouthpieces and other accessories strategically located behind the handlebar in a rotating storage drawer. Interface elements and electronic controls were developed for ease of use.

The new design of the pressure-formed housing reduces the weight of the product, making it one of the lightest units for the medical industry. Pressure-forming offered low tooling costs and faster speed to market than injection molding. The housing facilitates an effortless assembly in the manufacturing process and installation procedure.

The dental product design earned numerous awards, including a MDEA Silver award, Good Design award and a Multi-Part Enclosure award.

Design Team: Cesaroni Design & Gendex

Gendex Dental Systems and Cesaroni Design product designers developed this diagnostic imaging product. The engineering was handled by our client, while we focused on optimizing a lightweight structure. We worked closely with our client's engineering team to understand assembly and service requirements.

Multiple medical product design concepts were generated, all of which satisfied the project objectives. We then implemented the chosen concept in 3D CAD. The resulting part files were shared with Gendex's development team for further review.

The adjustable telescopic column is one of the most significant elements of the design. This component makes the unit extremely compact. It also enables the system to accommodate patients of all sizes, including children and wheelchair-bound patients.

Ergonomic diagrams assisted the development team in analyzing the design for the handlebar and chin rest so that the patient is held in a stable and comfortable position. Molded polycarbonate and carbon fiber patient supports are mounted on powder-coated handlebars.

The new product design increases workflow, giving the operator the ability to access mouthpieces and other accessories strategically located behind the handlebar in a rotating storage drawer. Interface elements and electronic controls were developed for ease of use.

The new design of the pressure-formed housing reduces the weight of the product, making it one of the lightest units for the medical industry. Pressure-forming offered low tooling costs and faster speed to market than injection molding. The housing facilitates an effortless assembly in the manufacturing process and installation procedure.

The dental product design earned numerous awards, including a MDEA Silver award, Good Design award and a Multi-Part Enclosure award.