- 2025

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- 2010

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- 2000

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- 1990

-

-

-

-

-

-

- 1980

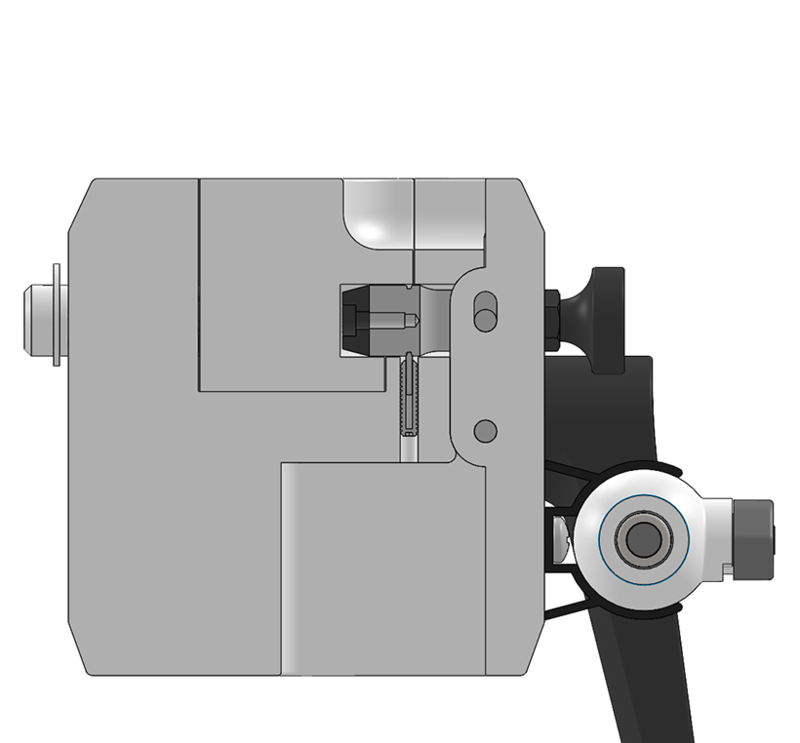

LECO Corporation

PX300 Grinder/Polisher

Design Team: Cesaroni Design & LECO Corporation

The Cesaroni Design firm collaborated with LECO’s scientists and engineers to create the new PX300 series, grinder/polisher. Both offices explored various aesthetic and ergonomic form factors that resulted in a reliable and robust industrial design. The PX300 features the latest in metallurgical technology and delivers a valuable, safe and clean solution for grinding and polishing needs. The PX300 also delivers exceptionally flat specimens.

The enclosure is a combination of injection molded plastic, fabricated steel and machined aluminum. The controls are traditional dial knobs and push buttons. The emergency stop button is strategically located for easy access and visibility.

LECO Corporation

PX300 Grinder/Polisher

Design Team: Cesaroni Design & LECO Corporation

The Cesaroni Design firm collaborated with LECO’s scientists and engineers to create the new PX300 series, grinder/polisher. Both offices explored various aesthetic and ergonomic form factors that resulted in a reliable and robust industrial design. The PX300 features the latest in metallurgical technology and delivers a valuable, safe and clean solution for grinding and polishing needs. The PX300 also delivers exceptionally flat specimens.

The enclosure is a combination of injection molded plastic, fabricated steel and machined aluminum. The controls are traditional dial knobs and push buttons. The emergency stop button is strategically located for easy access and visibility.