- 2025

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

- 2010

-

-

-

-

-

-

-

- 2000

-

-

-

-

-

-

-

-

-

-

-

-

- 1990

-

-

-

- 1980

Brunswick Bowling

The Frameworx Line, FreeStanding & Tabletop Seating

Design Team: Cesaroni Design & Brunswick Bowling

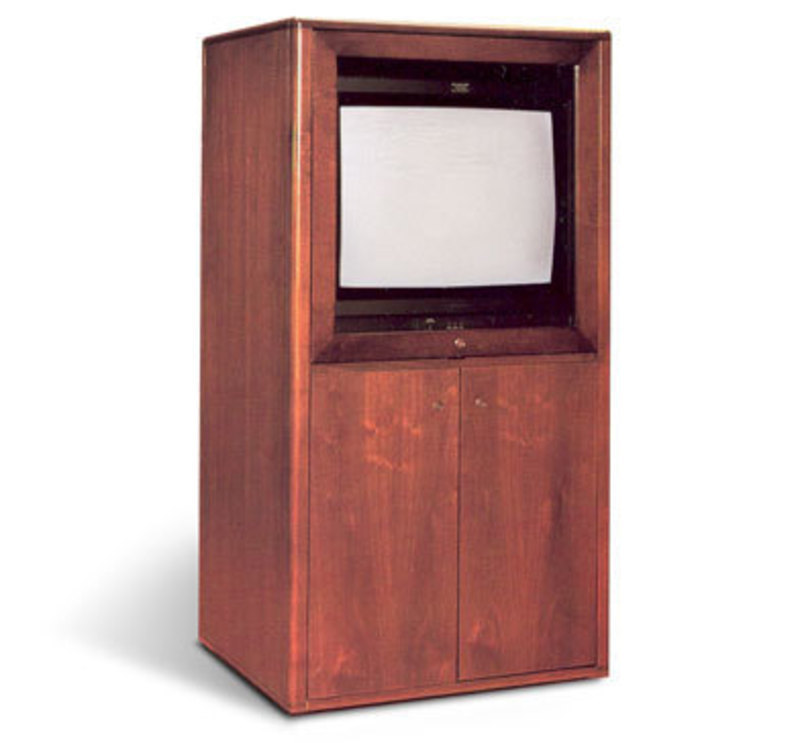

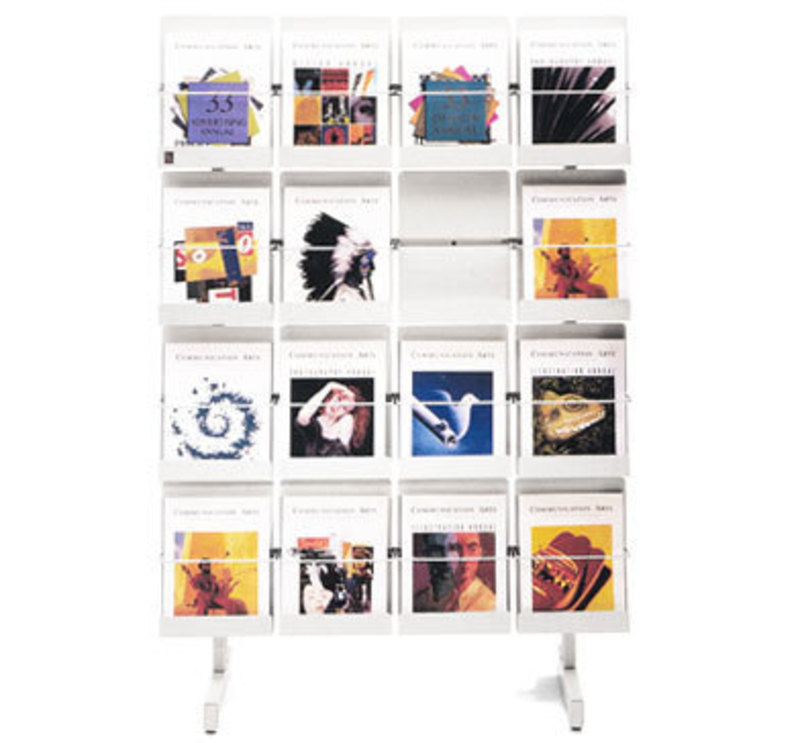

Brunswick Bowling teamed with Cesaroni Design to establish a new brand identity for bowling centers. The design challenge entailed developing a new capital equipment line which includes seating, tables, storage, ball returns, and scoring devices.

This recreational furniture line revolutionizes the way bowling centers function. Customized layouts and flexible seating configurations improve traffic flow and utilize more concourse space for food and beverages.

The design language was driven by factors such as appearance, cleanability, service, and durability. The highest volume item in the product line is the blow molded contour seat. The design team chose to manufacture the seating from polyethylene. This material is a cost effective solution compared to the traditional compression molded fiberglass profile seat.

Brunswick Bowling

The Frameworx Line, FreeStanding & Tabletop Seating

Design Team: Cesaroni Design & Brunswick Bowling

Brunswick Bowling teamed with Cesaroni Design to establish a new brand identity for bowling centers. The design challenge entailed developing a new capital equipment line which includes seating, tables, storage, ball returns, and scoring devices.

This recreational furniture line revolutionizes the way bowling centers function. Customized layouts and flexible seating configurations improve traffic flow and utilize more concourse space for food and beverages.

The design language was driven by factors such as appearance, cleanability, service, and durability. The highest volume item in the product line is the blow molded contour seat. The design team chose to manufacture the seating from polyethylene. This material is a cost effective solution compared to the traditional compression molded fiberglass profile seat.